+86 0371-69392107 Info@synthe-corp.com Request a Quote

About Mini Tube Furnace:

1.Thermogravimeter is a single temperature zone;

2.Resistance wire as heating element ,its continuous working temperature can reach 1000℃;

3.The heating tube body adopts quartz tube, can be used for the heating treatment of light materials;

4.The tube furnace equipped with a pair of stainless steel sealing flanges for sample heating to provide a vacuum environment;

5.Mini tube furnace also has gas supply system which can provide a variety of atmospheric environment for sample heating;

6.The weighing system can record the weight change of the tube furnace during the heating process;

7.And temperature control system,etc.

Note:More about tube furnace details welcome to contact us!

Video Link:https://www.youtube.com/embed/D30x6v8-1zc

|

Structure |

Use the aluminum alloy as the outer shell, to reduce the body weight and achieve more measurement accuracy. |

|

Working Temperature |

≤1000℃ for continuously |

|

Specification of the Tube |

Customized |

|

Heating Elements |

Heating Resistance Wire |

|

Tube Material |

Quartz(Optional) |

|

Power |

1.25 Kw |

|

Voltage |

240V, Single Phase, 50 Hz |

|

Temperature Control |

PID automatic control with 30 steps programmable |

|

Temperature Accuracy |

±1℃ |

|

Thermocouple |

K Type |

|

Warranty |

One year limited warranty Consumable parts such as processing tubes, o-rings, and heating elements are not covered by the warranty |

|

Note:We can provide customize according to your requirements. Welcome to consult us for more information. |

|

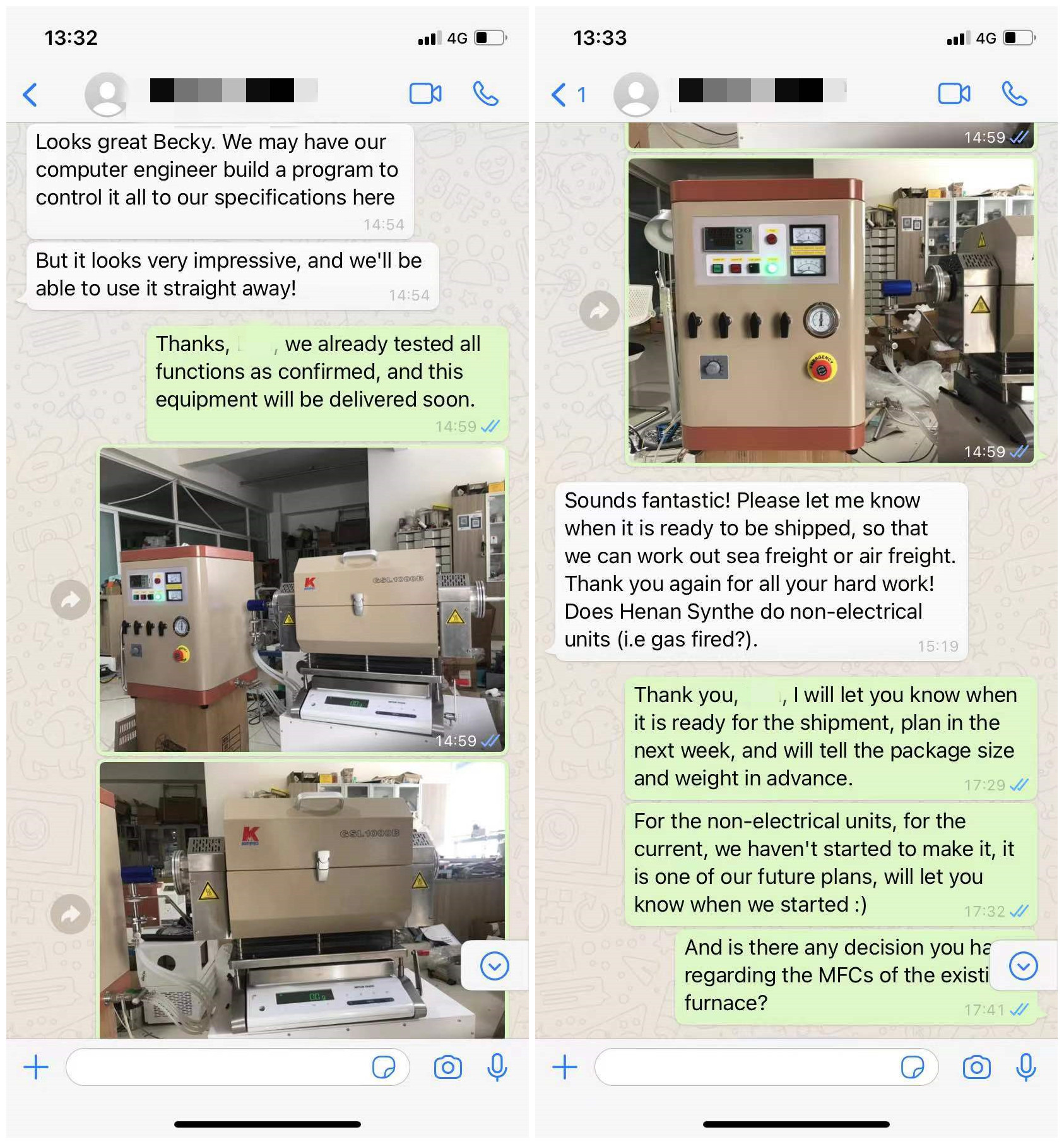

We have been engaged in heat treatment equipment for more than ten years, and have been committed to providing customers with solutions to meet their needs and being a solver of customer problems. Thank customers for their affirmation.