+86 0371-69392107 Info@synthe-corp.com Request a Quote

1.The furnace facilitate operation of firing cycles where atmosphere condition can be altered during operation cycle,

from oxidizing, (such as air to inert atmosphere), or argon/nitrogen to rough vacuum.

2.This type of furnace makes multi-atmosphere process in one cycle possible: binder burn out in air and parts sintering

under vacuum or inert gas atmosphere.

3.These furnaces are designed for accurate air/ inert gas flow rate control, accurate temperature control, excellent

temperature uniformity, long lasting performance and safe operations.

4.It is ideal for laboratories and small scale production.

Note:More about atmosphere vacuum furnace details welcome to contact us!

Video Link:https://www.youtube.com/embed/uAWlOv-1RC0

|

Furnace Structure |

Double shell steel case with cooling fan to keep outside case cool High purity foamed ceramic insulation for max. energy saving |

|

Voltage |

AC 208-240V, 50/60HZ, Single Phase |

|

Power |

15 Kw |

|

Max. Temperature |

1650℃ |

|

Chamber Size |

Depth 400mm × Width 330mm × Height 300mm(Customized) |

|

Temperature Control |

30 segments easy use PID programmable temperature controller |

|

Control accuracy |

+/-1°C |

|

Heating Element |

MoSi2 Heating Elements |

|

ThermocoupleK |

S Type |

|

Special Configuration |

Explosion Door Pirani Gauge |

|

We can provide design according to your requirements. Welcome to consult us for more information. |

|

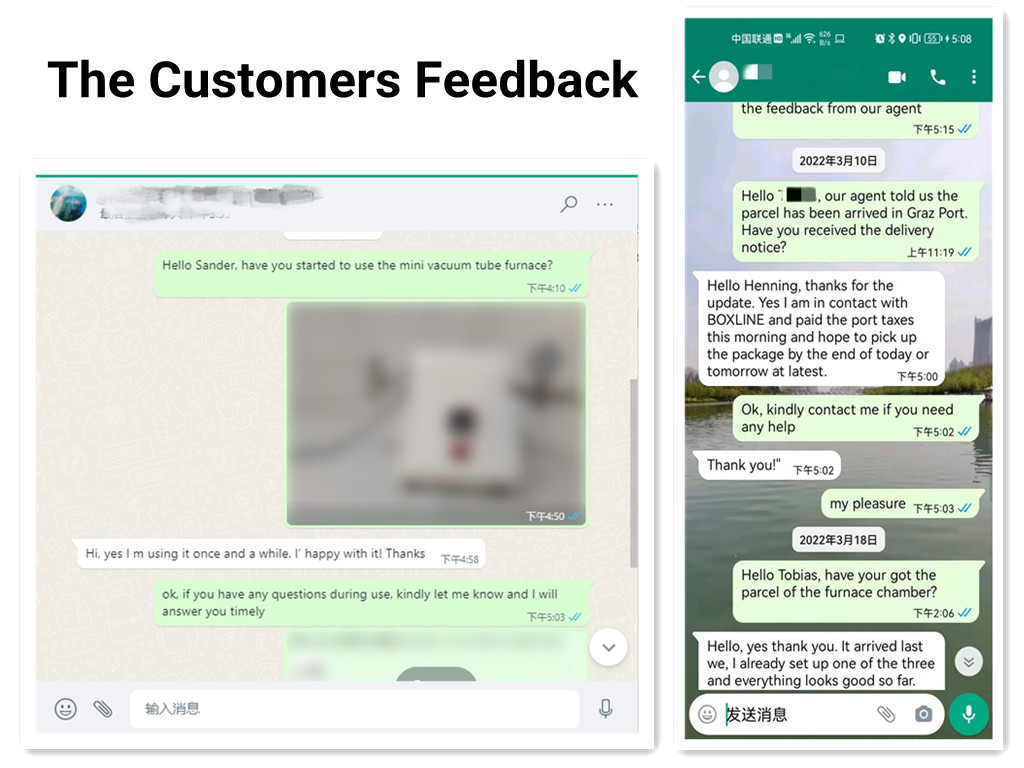

We have been engaged in heat treatment equipment for more than ten years, and have been committed

to providing customers with solutions to meet their needs and being a solver of customer problems.

Thank customers for their affirmation.